The manufacturing industry is gaining much momentum with 3D printing technology taking the pivotal role. This essential technology has brought about flexibility in manufacturing, and it is incredibly affordable. Indeed, this amazing trend of creating products has gained a lot of attention, and it is yet set to transform the industry.

But are you aware of how 3D printing service can be used to develop prototypes? Well, you will learn how 3d printing manufacturing companies differ from traditional models. You also would want to know why such 3D models are good. And before you even order 3D prints, these are the key transformations and enhancements to expect.

Improved Design

One of the commonly known ways to test designs was by use of prototypes for various uses. However, 3D printing services have embraced the flexibility even though the testing role is still used. You see, in the olden manufacturing processes, several stages had to be incorporated. The distinct stages demanded digital models that came with restrictions.

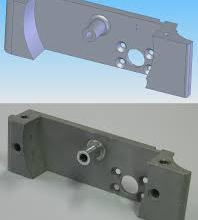

Some of such limitations included not being able to create a similar model of the final product. This connoted that there were fewer chances for great design and experimenting. However, thanks to 3D printing, the digital thread can be utilized in the whole process more accurate and in great 3D models.

Higher Application

It is amazing how 3D print machines can create up to 30 various types of products. And the printing process does not necessarily need to switch systems to achieve the rapid printing of one after the other. Thus, this 3D model really improved the utilization rate of the overall manufacturing sector. But here is another pick for you.

You probably agree that manufacturing processes are yet to be efficient. In some states, you will be surprised to learn that utilization is merely 75 percent. This points out that there is a certain fraction of materials and operations that are not utilized effectively. This could perhaps be due to the olden methods being used, which do not allow the adaptability of 3D prints.

Innovativeness

Yes, you can make further innovations. Thanks to 3D printing technology. See, 3D has gotten rid of the difficulties involved in assembling various parts together to develop a whole product. Through 3D, you can develop complex products that are highly valuable. You can also get custom 3D prints.

Designers and other participants in product creations can now be more innovative than ever. You see, 3D encourages innovation. This is the aspect that is increasingly enabling engineers and designs to come up with their great designs without much hassle.

In Conclusion

Everyone is receiving great services in hospitals due to advanced medical products being produced using 3D technology. This connotes that 3D has and will keep changing the lifestyles of many people around the globe. All these have been fueled by the ability to develop prototypes without limitations. Thus, the future seems to be brighter than you might even think. 3D is here to stay and enhance lives in various aspects.