The CNC punching machine offers an impressive range of benefits, so let’s take a look at what this machine is used for and how it can benefit your business.

What is a CNC punching machine?

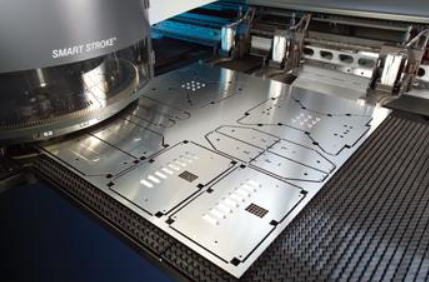

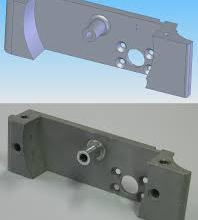

An acronym for computer numerical control, CNC punching machines are programmed to punch holes into sheets of metal. The machine works by producing a set of coordinates along the x and y axis and moving the sheet accordingly to replicate the intended design in punched hole form. The x coordinate controls the left to right motion of the sheet metal, whilst the y coordinate controls the up and down motion. This ensures the correct part of the sheet is always placed under the punching element.

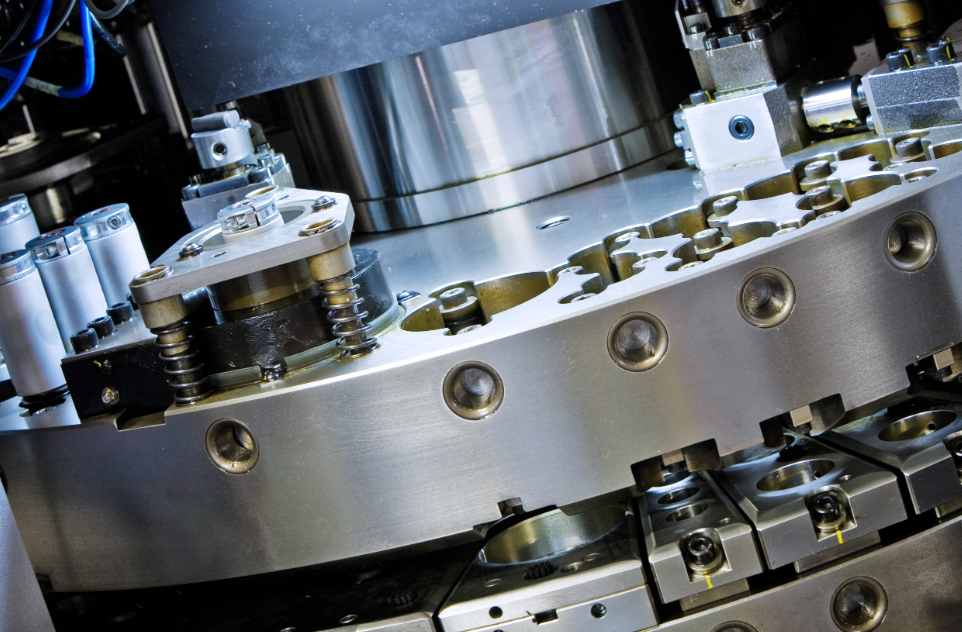

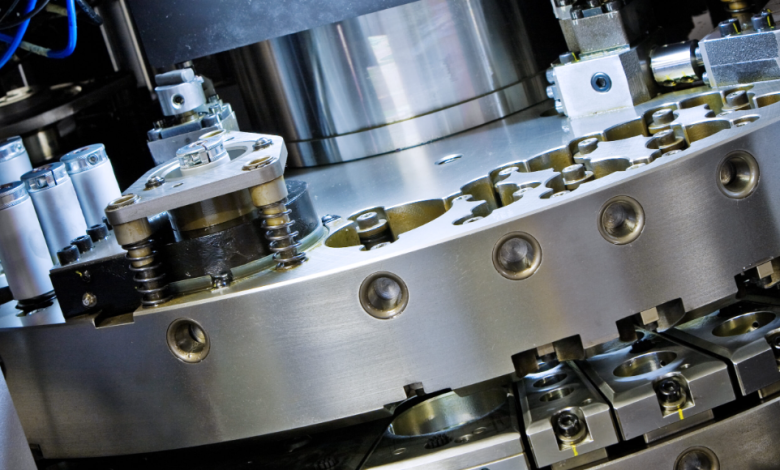

The CNC punching machine comes in two key forms. The first is the turret or multi-punching tool mould type, and the second is the type with a single linear rail of punching tools.

Key benefits

This type of machine can punch with a very high level of reliability and accuracy, which makes such machines the ideal tool for many applications where precision is vital. Examples include the aerospace, architectural and construction industries.

Opting for a high-quality punching machine can even help to drive cost efficiency for a business The economy of this kind of machine is attributed to the speed with which it can create a high volume of holes and the reduction in wastage this approach affords.

To find out which type of CNC punching machines might be suitable for your own application, it makes sense to consult a specialist stockist for guidance.

CNC punching machines are typically used to create holes in sheet metal, such as stainless steel, aluminium and brass, but can also be used on some plastics. It is also possible to create holes with a bespoke shape rather than simply a rectangle or circle; what’s more, unlike laser hole creation techniques, a CNC can be used to create elements such as countersinks, beads and louvres, making it a highly versatile piece of equipment.