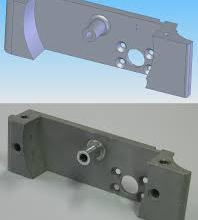

Thermal spray technology has come a long way since its inception. Today, the process has evolved beyond the early stages to become a widely accepted coating method in virtually every industry. The process can be used for applications such as repairing damaged parts, improving component performance, and extending the lifespan of components.

Depending on the desired property, the process involves materials deposited in a molten, semi-molten, or solid-state. Thermal spray coatings can be made from various materials, including metals, polymers, and ceramics. A wide variety of properties can be obtained with thermal spray coatings, from corrosion resistance to sound absorbance. Some advanced applications include wear protection, component repair, and thermal management.

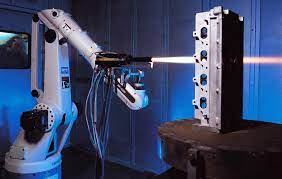

Thermal spraying focuses on applying these coatings and the properties of the resulting coatings. Advances in the field of thermal spraying have benefited from development in equipment and control systems, as well as the use of sophisticated modelling and diagnostics. When you need Plasma Spray services, contact https://www.poeton.co.uk/standard-treatments/plasma-coatings

Thermal spray processes are highly versatile and offer many advantages. They are beneficial for parts operating in harsh environments. For example, a 1% improvement in turbine efficiency can mean millions in savings.

One significant development in thermal-spray technology is the hypervelocity oxyfuel (HVOF) gun. It burns fuel and carries it through the nozzle, carrying the molten metal droplets along the way. These droplets are fragmented and rapidly solidified on the substrate. This process can be used for spraying large tanks and pipes’ interiors and coating the exteriors of a range of products, from industrial equipment to vehicles.

Artificial intelligence/machine learning in thermal spraying will be significant. New torch designs and data-driven modelling will also play essential roles in this development.

As the global energy demand continues to grow, thermal spray coatings will play a pivotal role in power generation. Power generation companies have recently announced their intentions to use a blend of renewable and fossil fuels to meet the growing demands for electricity.

Advances in the thermal spray industry include advanced spray-control systems and shop-floor thermal spray capabilities. These advances have led to a consolidation of applications and spurred new ones. Furthermore, these systems have improved the performance and repeatability of thermal spray operations. Moreover, these technologies are also being applied to produce unique ceramic formulations.

The need for increased efficiency in manufacturing drives advances in the thermal spray industry. Moreover, thermal spray coatings can extend the life of components and provide a superior level of performance. Lastly, the technology is expanding into new domains as it becomes recognised as a viable front-end design tool in other industries.