Some say the future of manufacturing looks to be very exciting. Others say the future is already here. There have been some very exciting advances over the last couple of years and the innovations look set to continue. Here are some of the manufacturing trends to watch this year.

1. Automation

Many UK rubber moulding factories have moved away from the traditional assembly-line systems of manufacturing and are embracing the benefits that automation has to offer, such as greater quality control and faster speeds. This automation could potentially lead to entire factories operating automatically without the need for human input.

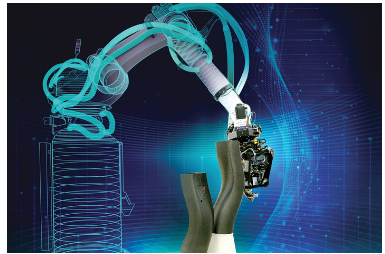

2. Robotics

Robots can improve the health and safety of workers by performing repetitive functions or lifting heavy loads. They can be programmed to work independently or in collaboration with a human workforce in order to achieve the best results.

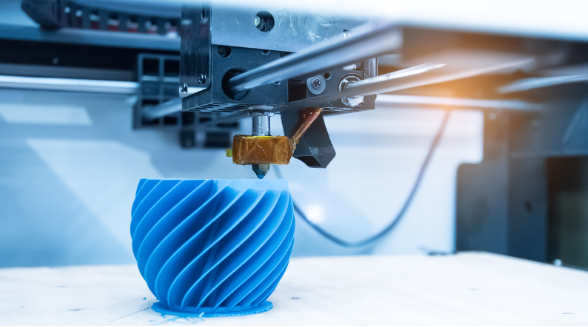

3. 3D printing

3D printing is popular in UK Rubber Moulding production facilities due to the ability to create small batches of products in a cost-effective manner without excessive waste. 3D printing will likely revolutionise the personalised products market and can be used to develop prototypes prior to launching full manufacture.

4. Cryptocurrency

Web3 could enable blockchain technology and cryptocurrency to be exploited, driving cost benefits and automating supply chain transactions. It is likely that in the future, manufactured products will be sold accompanied by an NFT (non-fungible token) digital certificate.

5. Sustainability

Consumers are clamouring for more sustainable products so there is likely to be a greater emphasis placed on the need for products that are manufactured to be reusable or recyclable. The modern consumer also wants their products to be functional and to enhance their lives, so we are unlikely to have seen the back of smart technology.

While there are challenges that will need to be overcome to exploit these innovations to their fullest extent, it is likely that the implementation of one or more of them in manufacturing businesses could alleviate staffing pressures, deliver cost efficiencies, and improve the quality of the output that is produced.